EPDM Floor Coating

EPDM granule is a coating material used in sports floors and children’s playground floors. The raw material of EPDM granule, whose open name is Ethylene Propylene Dianene Monomere, is rubber.

How to Apply EPDM Floor Coatings?

– The asphalt or concrete floor with correct slopes is first cleaned from all kinds of dust, dirt and moisture.

– Then a layer of primer (Ethyl acetate, polyurethane binder mixture) is applied to the floor with the help of rollers.

Primer is the layer that ensures that the floor and the floor covering material are firmly bonded to each other. – After the primer layer dries, the casting process of the 8mm thick SBR granules layer, which is the first stage of the application, is performed. First, SBR rubber granules of 1-3mm caliber are mixed with 18% polyurethane binder. (EXAMPLE 14 kg granules should be used per square meter to obtain 20 mm thickness from SBR granules of 1-3mm caliber). Then the mixture is laid on the ground by compacting with the help of a trowel. The drying time of the black colored SBR granule layer is approximately 10-15 hours. During this time, the ground should not be entered. –

– After curing is completed, 1-3mm thick EPDM granules are mixed with 20% polyurethane binder and laid on the black layer. To obtain 5 mm thickness with 1-3mm caliber EPDM, 5 kg EPDM and 1 kg binder should be used per square meter.

– Thus, your multi-purpose field is prepared. The drying time of the EPDM granule layer is approximately 24-36 hours. During this period, the ground should never be entered. The area should only be used after curing is complete. Finally, the desired playing lines are drawn on the field with polyurethane-based line paint and the field is ready for use. Our system is under our company’s 2-year warranty against application and installation errors.

- Measurement of dust content – EN 933-1.

Density of filling materials – EN 1097-3.

Particle shape of fillers – EN 14955.

Evaluation of synthetic fillers – FIFA Test Method 11 (TGA).

Color change – BS EN 20105-A02:1995.

Artificial decomposition – EN 14836:2005

Toy Safety – EN 71-3 Test reports are available.

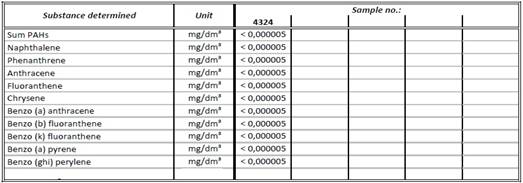

The results of the ANTICANCEROGEN content test on the products are as on the right.

EPDM is a highly flexible material as it is produced from granular rubber. For these reasons, it can easily adapt to all kinds of conditions. The sun of summer or the cold of winter cannot damage this material in any way. It is very resistant to impacts due to its elasticity. Being elastic also helps the material to take any shape. EPDM granule, which is a very durable product due to its structure, does not change according to weather conditions. In this material, which is resistant to every situation, events such as stretching, expansion and shrinkage never occur. In this way, it can be easily used in summer heat and winter cold. EPDM granule is not a substance that is colored later. In this material, which does not use a dyeing method, there is never a situation such as color fading. Its colors can remain intact for years. You can use every color you can think of in this material. EPDM granule, which has a wide range of color options, will give you the chance to choose the color you want. You can easily use the color you choose in the floor covering of your sports area.

Contact us for detailed information about EPDM Floor Coating.

01 RED

02 DARK GREEN

03 LIGHT GREEN

04 DARK BLUE

05 LIGHT BLUE

06 ORANGE

07 YELLOW

08 GOLDEN YELLOW

09 COFFEE

10 ANTRASIT

11 ANDESIT

12 IVORY

13 PINK

14 PURPLE

15 WHITE

16 CHROME GREEN

17 RASPBERRY